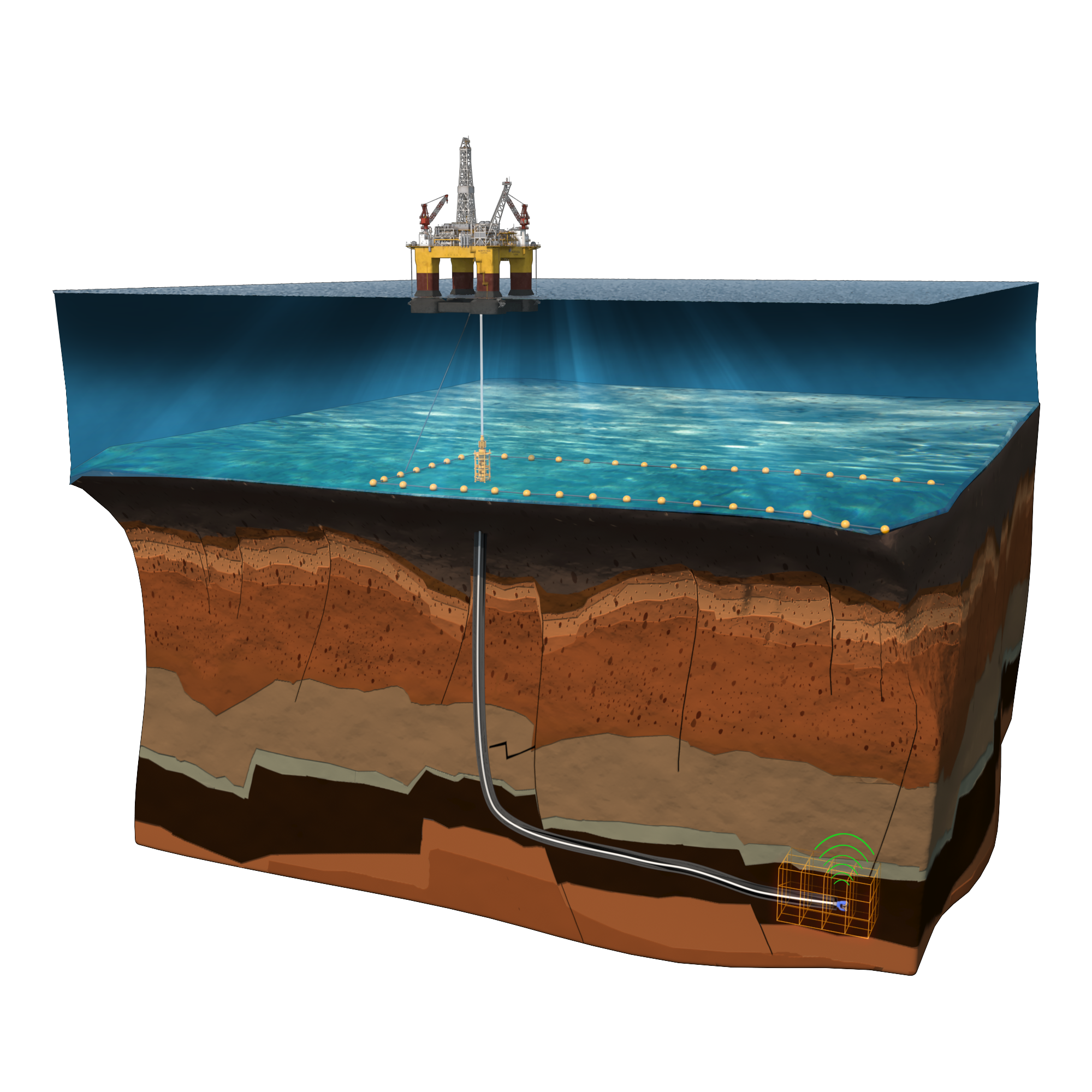

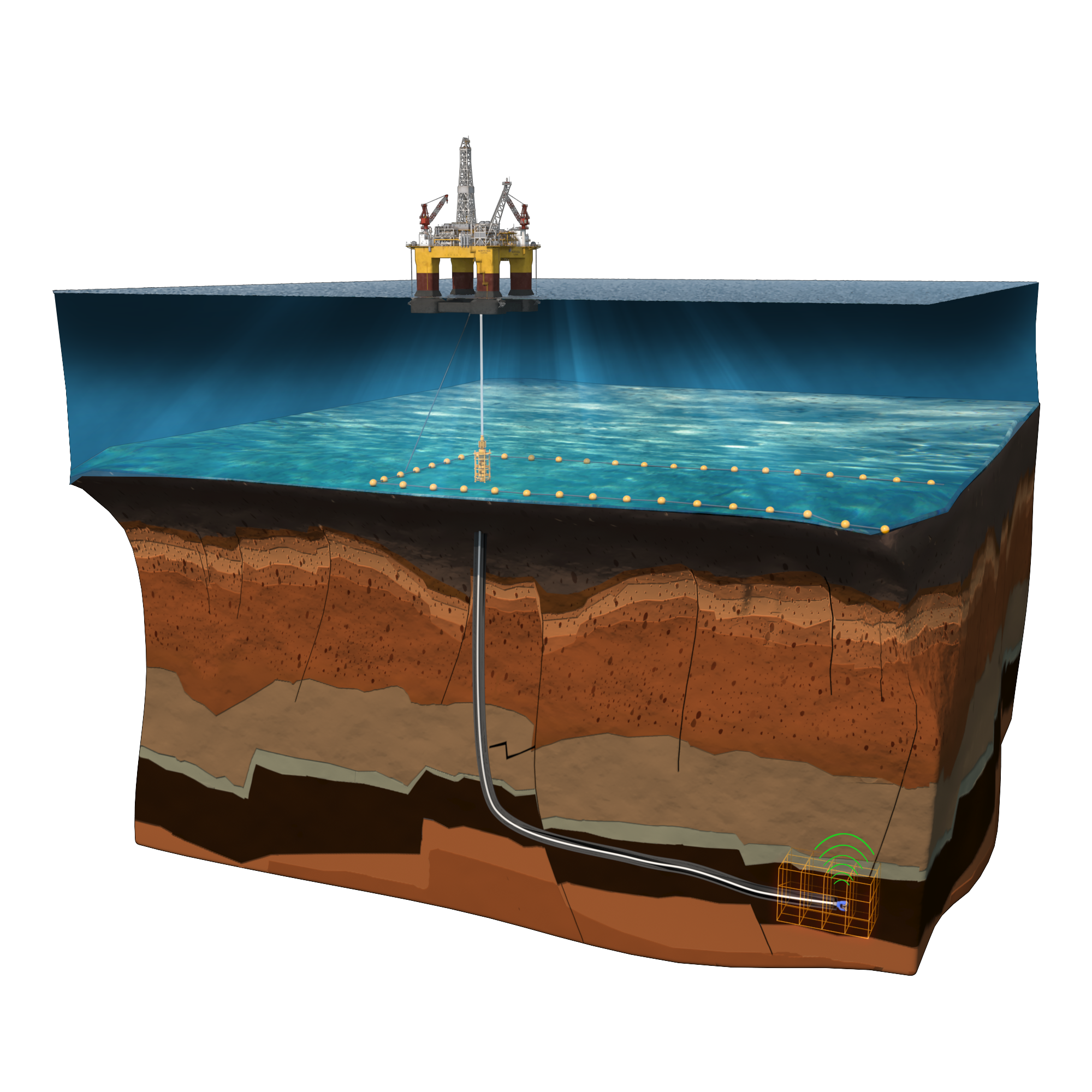

Drilling wells offshore is a costly and complex operation. Conventional methods for tracking the drill bit during drilling suffer from uncertainties increasing with the length of the well. Imperfections in subsurface models further complicate navigation of the drill bit relative to the target rock formations and hazardous areas. DrillWatch provides consistent meter-level precision throughout the length of the well and has the ability to sense geological structures ahead, with no interference with drilling instrumentation and operations. To do this, OCTIO deploys a standalone seismic sensor cable to the seabed. OCTIO’s Guardian Software processes the sounds emitted by the bit in real-time to accurately position the bit itself and to generate an image of the geology ahead.

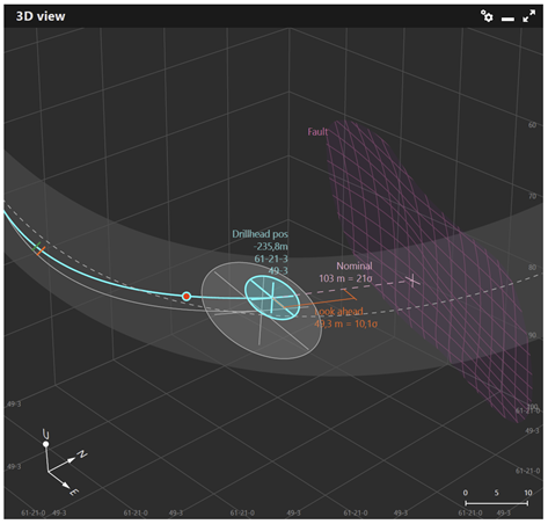

DrillWatch can contribute to meter-level precision in drill bit location throughout the length of deep, horizontal wells. The location of the drill bit is in units of seismic time, accuraly following the seismic map. The drill bit position is known with a 2-3 meter lateral precision.

With look-ahead capability, reflectors more than 200 m ahead of the drill-bit can be localized.

As an addition, DrillWatch can monitor for fractures caused by loss of drilling fluid, cement integrity, XLOT and injection test. It detect and accurately localize microseismic activity in the rock formations surrounding the well path, to ensure caprock integrity.

The drill bit creates noise while drilling, sending acoustic signals. The continuous passive recording of drilling vibration signals emitted during the drilling of the well, provides a seismic while drilling (SWD) dataset, which is investigated as a reverse vertical seismic profile (RVSP). These effective measurements are used for real-time monitoring of the drilling progress, both in terms of geosteering the drill bit and predicting formation properties ahead of the bit.

To read the acoustic signals, DrillWatch can use either already existing infrastructure (PRM), or the DrillWatch cable system. The service is hardware independent.

The footprint on the rig is minimal. There are no tools in the hole. Personnel are not needed offshore*. Readings are in real-time in order to make decisions as the drilling operation is ongoing to optimize the placement of the well.

*If sufficient band widt

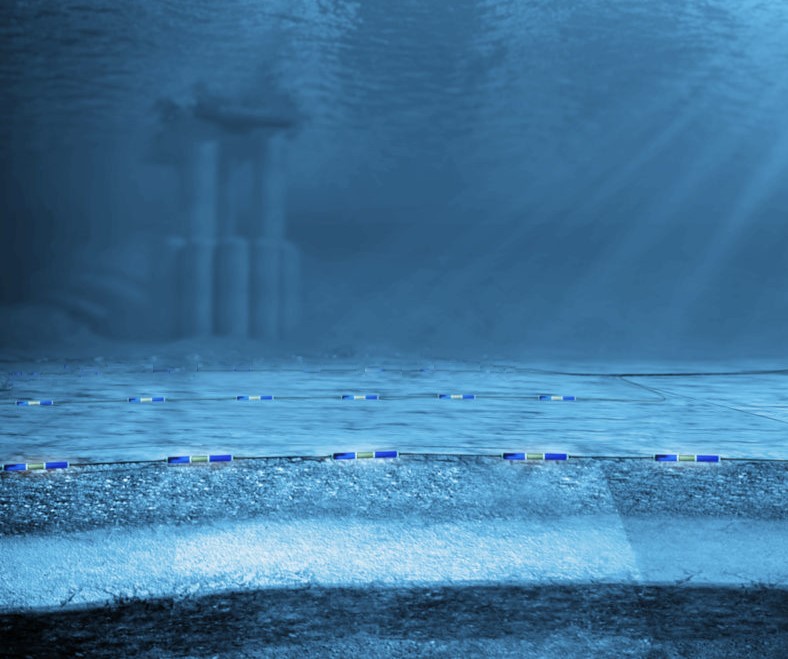

OCTIO’s cables consists of either 100 nodes or 240 nodes. The spacing between nodes are 25 m to ensure good quality readings of the acoustics from the drill-bit.

The cable is placed on the seabed above the area where the well or wells are to be drilled. The geometry of the cable layout on the seabed is optimized onshore previous to bringing the cable to the field.

OCTIO can deploy the cable either from an Anchor handling vessel or a PSV vessel already on Operators contract. The vessel will only be utilized for mobilizing and demobilizing the cable and is not needed during the monitoring phase.

The cable is connected to the rig, enabling real-time monitoring of the drill bit placement with high accuracy.

No trenching is needed for laying the cable. Its anchors supplied by its own weight will keep the cable in place.

The DrillWatch cable system is highly redundant with to-way signals sending and 25 years lifetime on seabed-spec.

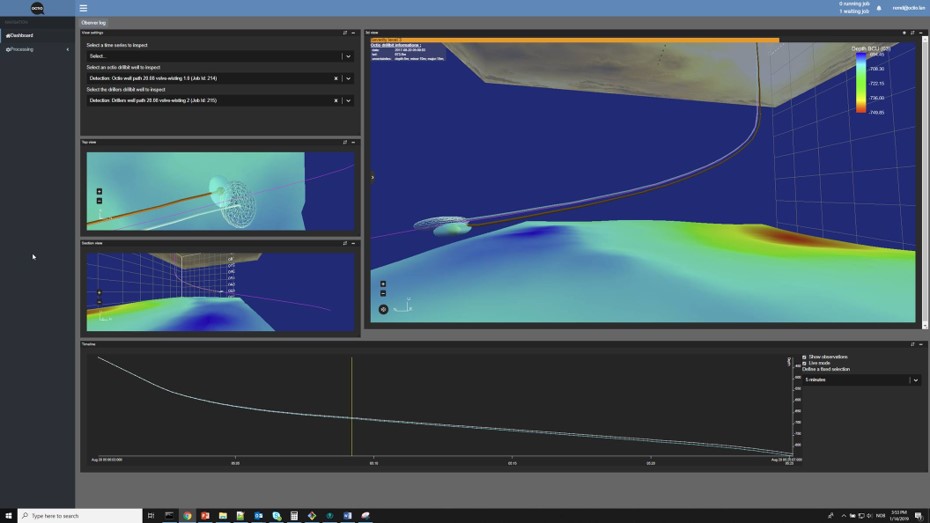

OCTIO’s software Guardian processes the sounds emitted by the drill bit in real-time in order to accurately position the drill bit and to generate an image of the geology ahead.

Real-time seismic monitoring is used to improve decision-making and safety during well drilling and injection operations. For those applications, a short reaction time is required.

The Guardian software features noise removal algorithms. The sofware displays drill-bit positioning with meter-level accuracy, displaying the much smaller uncertainty ellipse, guiding the driller to correct the path ahead. Simultaniously Guardian will display look-ahead info, showing how horizons are approaching. A usefull history line for navigation through microseismic events is buildt in to the software. It displays microseismic event detection and location. Integrated visualization of all data types is available. The software also consists of a log interface for easy communication between interested parties. Different levels of alarms will be activated when drillers are starting to deviate from the originally planned drilling trajectory. The Guardian software has alarm handling, including alarm push on smartphones.

In 2017 OCTIO deployed the DrillWatch cable on the seabed around the rig drilling on the Wisting field in the Barents Sea for the operator OMV. The purpose of this particular operation was to monitor well integrity and reservoir performance during the drilling operation and the well testing. This was the first time worldwide that an operation like this was carried out offshore. The placement of the drill-bit was localized with an accuracy of 2-3 meter laterally.

In 2018 OCTIO processed data gathered from Granes PRM system recorded as a well had been drilled on the field. It was validated that passively collected seismic-while-drilling data at Grane can be utilized to look ahead of the drill bit. Using an ocean bottom cable, DrillWatch can produce VSP information in real-time while drilling without the need to stop and pull the drill string for wireline deployment.

In 2020 OCTIO ran data from the PRM system from a well drilled on the field

In 2020 OCTIO processed data from the Ekofisk PRM array which had been passively monitoring as a portion of a well was drilled. The output was utilized to extract drill-bit seismic data for 3D RVSP imaging below the highly deviated wellbore. OCTIO obtained a 3D depth image extending far below the well track. The 3D RVSP image provides complementary information to the existing broadband LoFS images and demonstrates the potential of drill-bit seismic lookahead imaging to provide additional detail and relevant information for accurate placement of infill wells. The conclusion shows that by using a (permanent or temporary) cabled ocean bottom array, drill-bit seismic data can be acquired in real time. A detailed lookahead image can be produced while drilling is continuing to aid in optimizing well placement without the need to interrupt the drilling for additional logging.